A bay window is a structural feature that demands a treatment engineered to match its complex geometry. Getting this installation perfect is the difference between a high-end designer finish and a cheap, frustrating disappointment. Bay window shutters offer the only fully integrated and permanent solution.

Standard curtain tracks or blinds often do not meet the functional and aesthetic requirements of a bay window. This leads to the obstruction of space, reduced light transmission, and a mismatch with the architectural design.

So, how do designers get it flawlessly right?

The secret lies in rejecting guesswork. The custom bay window shutter is the single, uncompromising solution. For the professional fitter, the process is less about decoration and more about precision joinery. We deal in millimetre tolerances, not aesthetic guesswork, ensuring the finished product enhances the architecture rather than compromises it.

Phase One: Mastering Structural Geometry and Tolerance

You cannot afford to treat a bay window as separate units. The entire structure has to be addressed as one cohesive install. This is where the experienced fitter differentiates between the two core bay shapes:

- Splayed Bay (The Soft Arc): Common in Edwardian builds, these bays feature gentle, obtuse angles (often 135° or 150°). Our challenge here is maintaining the structural integrity of the joinery between the panels. Our frames must integrate custom-machined angle posts (or “decouplers”) to transition smoothly, eliminating the opportunity for light bleed at the corners.

- Box Bay (The Sharp Angle): These are common in Victorian terraces and defined by distinct 90-degree internal corners. In a Box Bay, the shutter panels often hinge directly off a dedicated corner post (or ‘T-Post’). This post manages the weight transfer and ensures the panels don’t ‘rack’ or drop over time, which is a key failure point in amateur installations.

Standard retail solutions consistently fail the tolerance test here, leading to unsightly gaps, structural weakness, and compromised thermal efficiency. To get that refined look, the custom bay window shutters frame simply has to be engineered to the bay’s unique footprint.

Phase Two: Operational Mechanics and Style Specification

Once the structure is sound, style choice is purely a matter of required functionality. We advise our clients based on strict operational requirements:

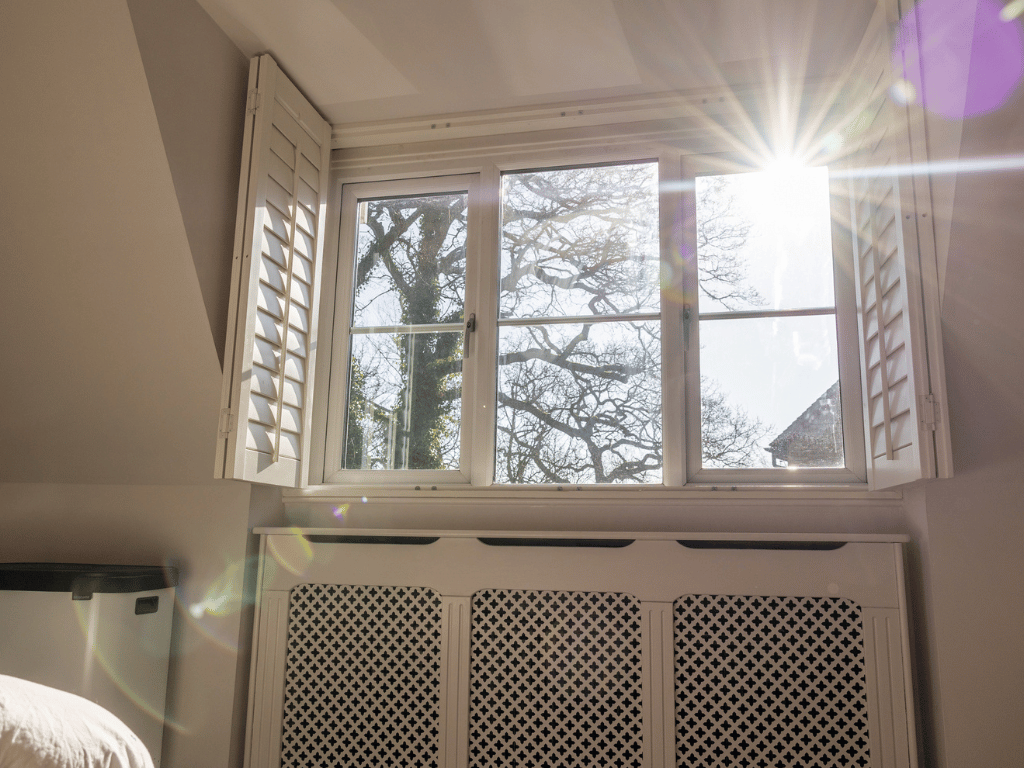

1. Café Style Bay Window Shutters (Targeted Privacy)

This café style shutters style features panels covering the bottom section only.

- Goal: To isolate privacy control at the ground level while maximising light transfer through the upper tier.

- Best For: Street-facing living rooms where privacy is paramount below 1.5m, but the room needs to remain exceptionally bright.

2. Tier-on-Tier Bay Window Shutters (Full Utility)

The Tier on Tier bay window shutters uses two sets of independently operational panels, stacked vertically within the same bay frame.

- Goal: Total flexibility. The top tier can be folded back entirely or louvred open, while the lower tier remains closed for security and privacy. This is the most versatile option for thermal and noise management.

- Best For: Bedrooms or multi-purpose rooms where light conditions and privacy needs fluctuate dramatically between day and night.

3. Full Height Bay Window Shutters (Structural Symmetry)

Full Height shutters cover the entire window length. For stability, this style almost always requires a horizontal dividing rail positioned to align precisely with the window’s original glazing bar (mullion).

- Goal: To provide an unbroken architectural line, maximizing insulation and creating visual flow. The dividing rail is crucial for preventing warping on taller panels.

- Best For: Formal spaces where structural impact and noise reduction are primary concerns.

Beyond the Panel: Fine-Tuning Your Design with Louvre Size and Tilt Rods

The panel choice handles the functionality, but the details, specifically the louvres, are what determine the final look and light control ratio:

- 63mm Louvres (Traditional): Best suited for smaller, period-style windows with low recess depth. They block the most light when closed, but the view out feels more broken up when they are open.

- 89mm Louvres (Contemporary Standard): This is the industry standard. It offers the best balance between sightlines and privacy, working in nearly all recess depths.

- 114mm Louvres (Max View): Ideal for large, modern extensions. They maximise the view out, offering the cleanest, most minimalist look, but require significant recess depth clearance, a non-negotiable measurement.

You must also choose your operational control: the tilt rod. A visible central tilt rod provides a classic plantation aesthetic. Conversely, a hidden tilt rod (adjusted via an internal, edge-mounted mechanism) creates a cleaner, uninterrupted surface – the default choice for minimalist, high-end interiors.

Phase Three: Material Specification and Shutter Furniture

A designer treats bay window shutters as fixed joinery. They must be specified to outlast the home.

Materials: Hardwood remains the gold standard for its rigidity and lightweight performance on large bay panels. However, for areas of high moisture or direct sun exposure, a high-quality composite is the only acceptable spec, guaranteeing that the bay window shutters will not warp or degrade.

Shutter Furniture and Finish: The hinge finish is not a trivial choice. It is the final point of detail for perfectly chic look.

For traditional bays, opting for decorative brushed chrome or period-style brass hinges adds a deliberate, luxurious accent that should tie into other room hardware. For a modern, seamless look, specifying colour-matched or hidden hinges ensures the panel lines remain perfectly unbroken, creating a monolithic wall of light control. Ignoring these technical choices prevents the entire installation from achieving a truly custom-fitted grade.

The Benefit of Custom-Engineered Bay Window Shutters

An ill-fitting shutter instantly registers as cheap and compromises thermal performance. By commissioning a local, made-to-measure bay window shutter install, you guarantee two non-negotiables:

- Zero Light Bleed: The perfectly profiled frame eliminates all light gaps, maximizing the thermal and acoustic air buffer.

- Operational Longevity: The correct installation method prevents panels from ‘racking’ or drooping, ensuring reliable operation for decades.

Solve the Structural Challenge of Your Bay Window with Excell Blinds!

For commercial clients, this level of precision translates directly into asset value. Shutters in hotels, restaurants, or office spaces require maximum long-term durability to minimise maintenance costs, and the elevated, clean aesthetic directly reinforces the brand’s professional image.

Don’t settle for off-the-shelf guesswork when designing your property’s most prominent feature. Engage local bay window shutters experts who understand the unique structural and operational demands of Liverpool architecture. We specialize in engineering solutions that guarantee a perfect fit and maximum long-term durability.

Contact Excell Shutters today to discuss your project and schedule a precision measurement consultation!

Excell Shutters, based in the North West, specialises in the bespoke manufacture and professional installation of interior shutters for homes and commercial premises across all of our service areas. We guarantee a perfect fit and long-term performance.